Installation Of Cement Plant Kiln

Analysis of installation and commissioning of cement rotary kiln

Due to its large size, heavy weight and high precision requirements, the rotary kiln is generally transported to the installation site by semifinished products of segmented and sub Installation of Rotary Kiln Bricks BY RHI Preparatory work General information (lining chart, lining method, mixing ratio, packing list, working Brick Calculator and Installation Procedures INFINITY FOR 2025年3月22日 The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide The Cement Plant Operations Handbook International 2023年8月17日 FLSmidth’s ROTAX2® and 3base kilns deliver the best in rotary kiln designs With the ideal temperature profile and material retention time, these rotary kilns play a key role Rotary kilns for cement plants FLSmidth CementIn cement plants, drying and preheating of refractories in all the equipments, eg, cyclones, kiln, TAD, hood, and cooler, are needed The hot air generated for drying purpose must have Refractory Design, Installation, and Maintenance SpringerLinkIn order to overcome abovementioned defective, the invention provides a kind of largescale cement production line rotary kiln installation method, this is installed, and not only method isInstallation method for rotary kiln for largesized cement

.jpg)

How to Make the Installation of Cement Rotary Kiln More

2024年7月1日 The installation of the cement rotary kiln is a passionate and dynamic process We must prepare and welcome its joining with all our enthusiasm Only in this way can we 2025年4月27日 Lime rotary kilns can be divided into cement kilns, metallurgical chemical kilns and lime kilns according its processing raw materials treated According to the drying method are wet rotary kiln and dry rotary kiln, the Lime rotary kiln install in cement plantThe rotary kiln is the heart of a cement manufacturing plant Cement kilns have all chemical ingredients These ingredients are at a broad range of gas temperatures from 100° to 1650°C The emissions contain: High concentrations of alkaline Raw Mill – Kiln Application in Cement IndustryAs a cement plant engineering solution supplier, we provide complete solutions for cement plant construction, including design schemes, land construction, equipment installation, pipeline installation, electrical installation, and Cement Plant Engineering Cement Plant EPC Installation of Rotary Kiln Bricks BY RHI Preparatory work General information (lining chart, lining method, mixing ratio, packing list, working instruction )Brick Calculator and Installation ProceduresThe kiln hood and the kiln tail chamber are static equipments that are connected with the front and rear equipment of the rotary kiln; the pulverized coal combustion device transfers the heat to the cement raw material by burning Analysis of installation and commissioning of

.jpg)

Everything you need to know about Refractories

Although faster to install than brick, monolithic products require careful curing and dryout before being put into service Specialties: This class includes calcium silicate boards, ceramic fibers, and mineral wool These insulating materials Cement kiln safety is a critical aspect of plant operations, requiring a proactive approach and strict adherence to established protocols By focusing on key areas such as PPE, LOTO procedures, training, and emergency response planning, Cement Kiln Safety Protocols: Ensuring a Safe2022年2月9日 CEMENT PLANTS Process and refractory choice Technical Meeting Cement, Ternary phase diagram CaO SiO2Al2O3 3 Technology evolution 4 NSP : Suspension CEMENT PLANTS Process and refractory choice Seven 2023年8月17日 The kiln is the heart of the plant – what an entire cement plant is dimensioned around, and where most of the final chemical reactions take place So it’s not surprising that a Rotary kilns for cement plants FLSmidth CementAGICO integrates kiln engineering contracting and installation for lime kiln furnaces We can supply vertical lime kilns, double chamber kilns, annular shaft kilns, double beam kilns, rotary Lime Furnace Lime Kiln Furnace 2001200 tpd cementplantsAnd during the installation of the sectors the kiln is available for turning That means installation and maintenance are more flexible We offer all types of Cement plant kiln Spares A Kiln Webber India

.jpg)

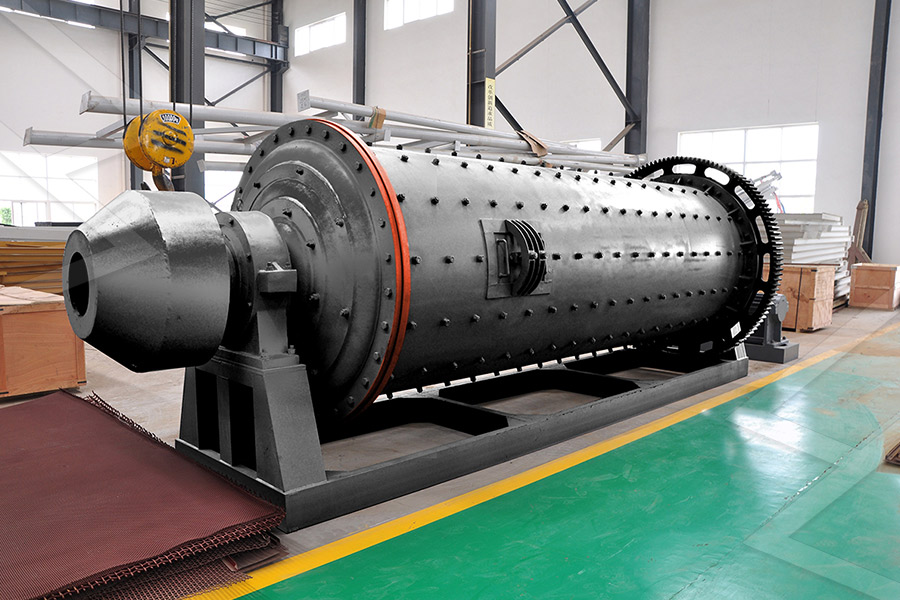

Achieving Optimal Cement Plant Performance through Girth

2023年3月4日 Girth gear alignment is a critical aspect of cement plant machinery maintenance that ensures optimal equipment performance and longevity The girth gear is an essential 2016年12月1日 Rotary kiln installation forms a very complex system, as it consists of various components which affect cement production However, some problems with particle settling Modification of the inlet to the tertiary air duct in the cement kiln The function of the static plant lining and how that can be achieved by different lining designs The installation of static plant linings Bringing the static plant lining into service Failure modes of Cement Kiln Refractories Course from International Cement What Is Cement Rotary Kiln Cement rotary kiln, also called cement kiln, is a pyroprocessing device used for calcining cement clinker in cement production linesIt is the main engine in the cement manufacturing process, commonly Cement Rotary Kiln Rotary Kiln Rotary Kiln Specialists in new projects offering a range of services, from refractory product supplier all the way to full installation partner Greenfield construction; Manufacturing and plant modernization; Serving the advanced engineering HWI Refractories Products/Applications for This reduces the capital costs of a new cement plant A dry process kiln might be only 70m long and 6m wide but produce a similar quantity of clinker (usually measured in tonnes per day) as a wet process kiln of the same diameter but The cement kiln Understanding Cement

.jpg)

Kiln Thrust Roller Rotary Kiln Thrust Roller Cement Plant

AGICO CEMENT supplies kiln thrust roller with high quality and competitive price, customization service, welcome to get more FREE information! The upward channeling force must be The kiln tyre, also known as the rotary kiln tyreAs a necessary part of rotary kiln, is used to transfer the entire gravity of the rotary kiln tube body (including the gravity of refractory bricks, Kiln Tyre, Rotary Kiln Tyre Ring – 180T Cement PlantIn short, a plant chemist must not only concern himself with the ultimate cement quality a kiln feed will deliver but must also design the mix to possess good burnability and coatability properties Kiln Refractory Requirement , properties Factors affect 2022年7月1日 The utilization of waste as an alternative source of energy in a cement kiln contributes to generation byproducts rich in chloride potassium, ie cement bypass dust Dust from chlorine bypass installation as cementitious Previous Post Next Post Contents1 KILN STARTUP PROCEDURES11 KILN STARTUP PROCEDURES2 11 Parameters to be tracked during preheat3 111 Preheater/Precalciner4 KILN STARTUP PROCEDURES INFINITY FOR CEMENT EQUIPMENTRotary kiln is the nucleus equipment in cement plant, its complex structure and heaviness, the adverse circumstances that will bear highaltitude, high temperature and high load capacity Installation method for rotary kiln for largesized cement

cementplantoperationhandbook PDF SlideShare

2016年5月27日 cementplantoperationhandbook Download as a PDF or view online for free 1 The basic components of a cement kiln system including a preheater, rotary kiln, and 2019年9月5日 The installation and commissioning process of the rotary kiln, as well as basic acceptance, pallet alignment, cylinder hoisting, wheel set, cylinder welding, kiln kiln tail seal installation Analysis of installation and commissioning of 2008年8月11日 In 2001, the first SCR system on a cement kiln began operation at the Solnhofer cement plant in Germany The plant has a production capacity of 1600 tons clinker/day and it Microsoft Word cementscrreportfeb2008docx2022年5月19日 Figure 1 Typical rotary cement kiln Figure 2 Cross section of kiln at the supports showing shell ovality and its effects on the refractory bricks Figure 3 Bottom view of CONTROLLING KILN CONDITIONS Bk Vibro2024年1月17日 Rotary Kiln Installation and Operation Instruction Free download as PDF File (pdf), Text File (txt) or read online for free This document provides installation and operation Rotary Kiln Installation and Operation Instruction2020年11月1日 An energetic and exergetic optimised Rankine Cycle for waste heat recovery from the chimneys of the Sabzevar cement factory is proposed in [16] to be used in the Evaluation of waste heat recovery technologies for the cement industry

.jpg)

Update on electric cement kilns

2022年6月15日 It is early days for cement kiln electrification but progress is happening both commercially and scientifically The next step to watch out for will be the first pilot installation 2020年11月29日 Performance of refractory lining depends largely on both the design and installation of the refractory lining The kiln, furnaces, or the reactors used in modern cement, Design, Installation, and Maintenance of Refractories3 Kiln System The kiln is the heart of the cement plant, where the raw mix is transformed into clinker through heating Equipment: Rotary kilns, preheaters, precalciners Technical The Comprehensive Guide to Cement Plant Costs: An In 2020年11月29日 The installation of monolithic lining is faster and easier than brick lining But the installation of monolithic refractory is more critical than brick lining 11610 Kiln Kiln is the Refractories for Portland Cement Manufacturing SpringerLink2023年5月22日 This will support cement plants to achieve TSR through kiln main burner as well In this regard, one cement plants in southern parts of India targeted to replace 25% of their Refuse Derived Fuel (RDF) Coprocessing in Kiln Main Burner in a Cement The kiln hood and the kiln tail chamber are static equipments that are connected with the front and rear equipment of the rotary kiln; the pulverized coal combustion device transfers the heat to the cement raw material by burning Analysis of installation and commissioning of

Everything you need to know about Refractories

Although faster to install than brick, monolithic products require careful curing and dryout before being put into service Specialties: This class includes calcium silicate boards, ceramic fibers, and mineral wool These insulating materials Cement kiln safety is a critical aspect of plant operations, requiring a proactive approach and strict adherence to established protocols By focusing on key areas such as PPE, LOTO procedures, training, and emergency response planning, Cement Kiln Safety Protocols: Ensuring a Safe2022年2月9日 CEMENT PLANTS Process and refractory choice Technical Meeting Cement, Ternary phase diagram CaO SiO2Al2O3 3 Technology evolution 4 NSP : Suspension CEMENT PLANTS Process and refractory choice Seven 2023年8月17日 The kiln is the heart of the plant – what an entire cement plant is dimensioned around, and where most of the final chemical reactions take place So it’s not surprising that a Rotary kilns for cement plants FLSmidth CementAGICO integrates kiln engineering contracting and installation for lime kiln furnaces We can supply vertical lime kilns, double chamber kilns, annular shaft kilns, double beam kilns, rotary Lime Furnace Lime Kiln Furnace 2001200 tpd cementplantsAnd during the installation of the sectors the kiln is available for turning That means installation and maintenance are more flexible We offer all types of Cement plant kiln Spares A Kiln Webber India

Achieving Optimal Cement Plant Performance through Girth

2023年3月4日 Girth gear alignment is a critical aspect of cement plant machinery maintenance that ensures optimal equipment performance and longevity The girth gear is an essential 2016年12月1日 Rotary kiln installation forms a very complex system, as it consists of various components which affect cement production However, some problems with particle settling Modification of the inlet to the tertiary air duct in the cement kiln The function of the static plant lining and how that can be achieved by different lining designs The installation of static plant linings Bringing the static plant lining into service Failure modes of Cement Kiln Refractories Course from International Cement